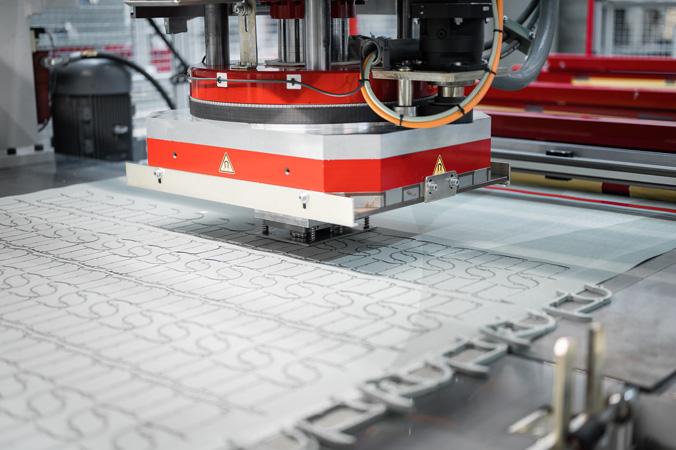

We offer a wide range of delivery forms to suit your assembly process and to satisfy your precise wishes and requirements. We can package and deliver your components separately, bundled, stacked, secured with stacking pins, arranged on a strip as adhesive as well as non-adhesive parts, in blister packs, small load carriers, on reel or in any other desired format.

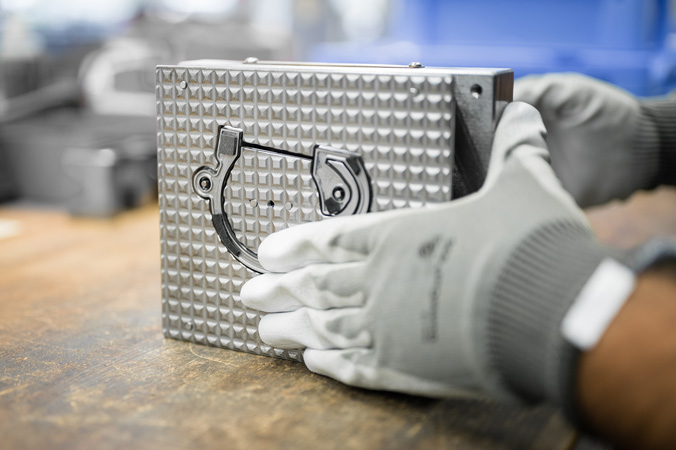

We aim to achieve optimum installation of products and handling of parts in our customers’ downstream assembly operations. We also aim to protect everything we supply against damage until they go for further processing.

We also strive to be as compatible as possible with the systems used by our customers, using interfaces such as EDI, EDIFACT or established platforms like SupplyOn to exchange information seamlessly up to the point of delivery and invoicing.

Optimum installation of products in downstream assembly processes combined with protection of all items against damage.