Home » Products & solutions » Seals

Sometimes it is the small and rather inconspicuous parts that are the most relevant. We tackle that issue on a daily basis: As one of the leading manufacturers of seals and Technical Parts, we here at SCHLÖSSER know full well that our solutions often deliver their benefits from concealment. It is therefore all the more important to know that you can depend upon them.

A seal – in simple and general terms – is there to keep systems tightly closed. In systems or machines that use different operating fluids (media), press forces or temperatures, seals are there to segregate functional spaces. They prevent substances and media (e.g. vapour, water, oil …) from escaping inside systems (parts, assemblies), or to reduced these material transfers to a tolerable level.

This means that seals serve different purposes:

Are you interested in our seals and technical parts? Or do you need a solution from SCHLÖSSER for a specific requirement? If so, please just get in touch with us: we are here to assist you.

Tel. +49 7572 606-0 Mon.-Thu. 8:00 a.m. – 4:30 p.m. Fri. 8:00 a.m. – 4:00 p.m. info@schloess.de

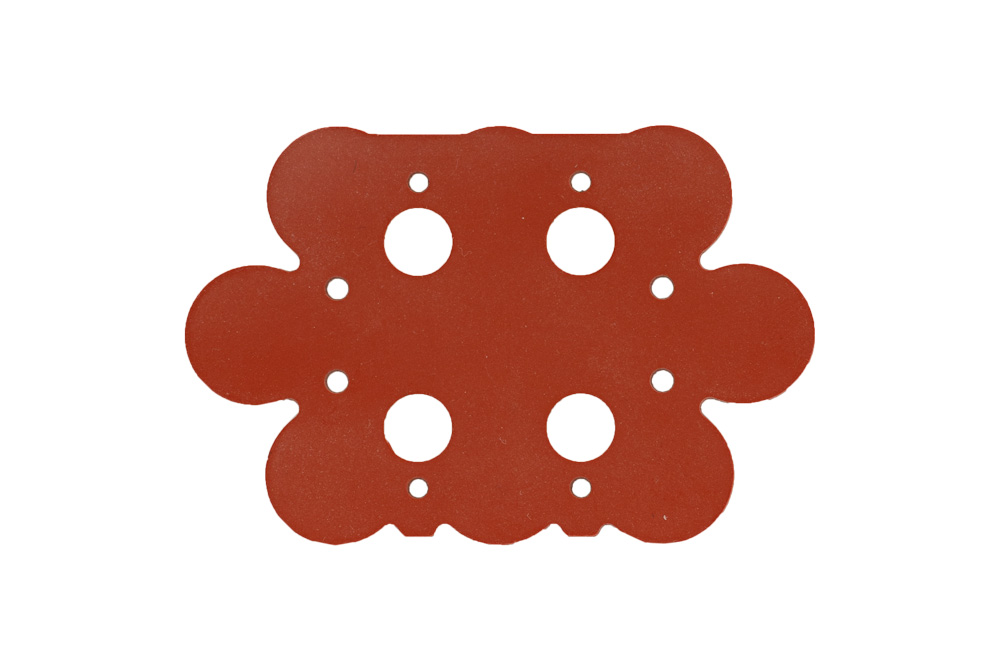

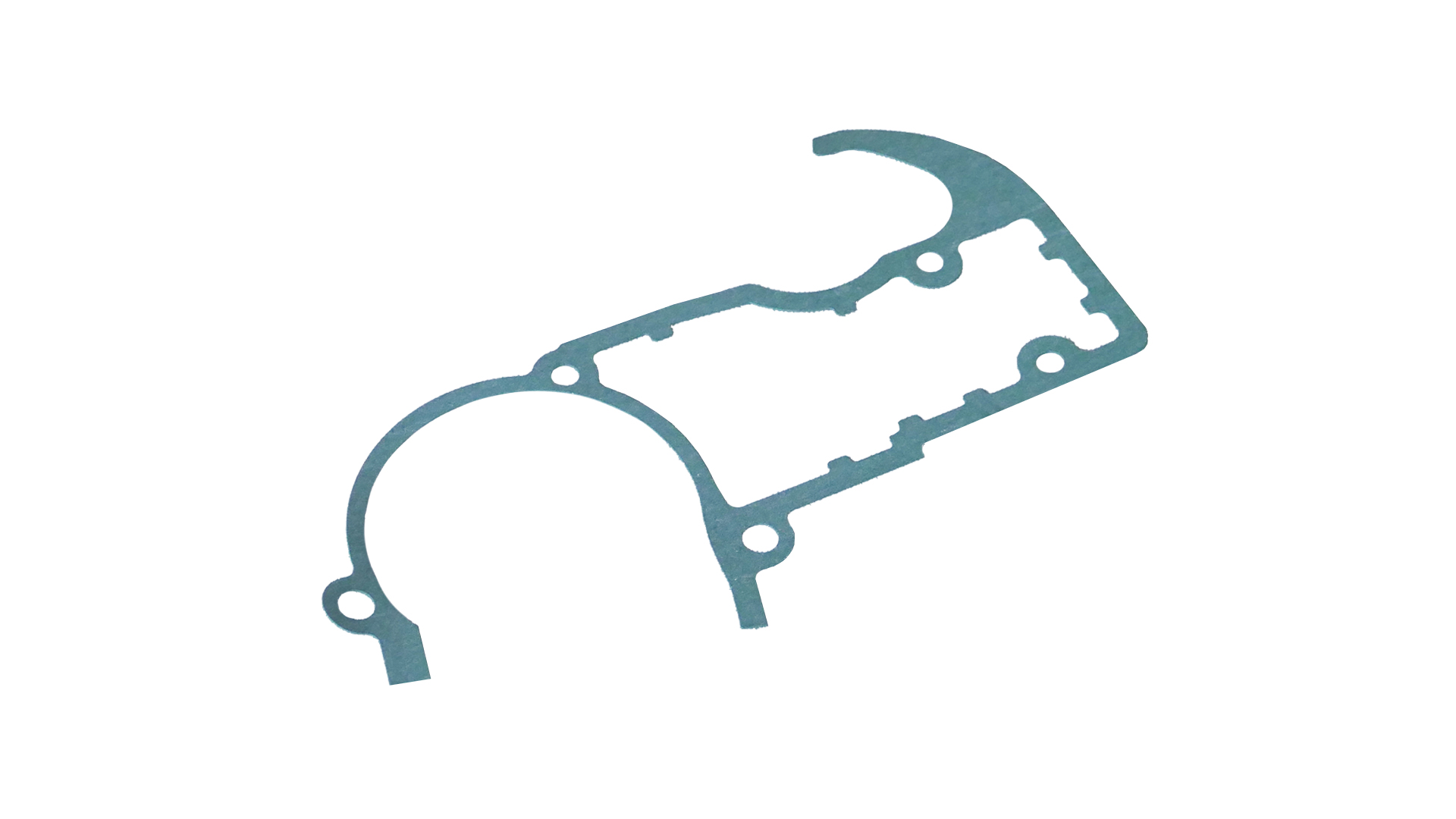

A fundamental distinction is made between dynamic seals (between two boundary surfaces that move relative to one another) and static seals where the boundary surfaces remain stationary. Examples of these are gaskets, profile seals or sealing compounds. SCHLÖSSER has specialised in the manufacture of high-end static seals, especially in the field of gaskets. The breadth of processing operations and materials involve SCHLÖSSER in devising what are often highly complex solutions. Individually adapted to suit the assembly of a given customer.

Here you will find a compilation of the most important questions and answers on various topics relating to seals.

A fundamental distinction is made between dynamic seals (between two boundary surfaces that move relative to one another) and static seals where the boundary surfaces remain stationary. Examples of these are gaskets, profile seals or sealing compounds. SCHLÖSSER has specialised in the manufacture of high-end static seals, especially in the field of gaskets. The breadth of processing operations and materials involve SCHLÖSSER in devising what are often highly complex solutions. Individually adapted to suit the assembly of a given customer.

The consequences of defective seals can be very serious. Here, we include defective seals as well as the use of unsuitable seals for a given application as well as incorrect installation or processing errors. This is because, if a seal fails to perform its central function – to seal systems and/or to partition off functional spaces – media can escape from or enter a given system. This problem is known as leakage.

The potential consequences of defective seals and of leakage can include:

As an experienced manufacturer of seals and Technical Parts, SCHLÖSSER fields a broad range of products for which we are a sought after and dependable partner across a vast array of different types of application. Primarily, we have specialised in the production of static seals (for stationary components). Our production operations span the following range of products:

As already explained, seals are used to separate media inside systems, and/or to prevent or to reduce substantially the potential for the migration of substances. The major properties of seals include seal integrity, process stability and durability and, in most cases, also a certain degree of elasticity (mechanical design). Application-specific requirements are added to this, which also entails the manufacturing processes as well as the materials used for these seals, e.g.:

To manufacture its seals, Technical Parts, punched parts and others, SCHLÖSSER primarily used three production processes:

The production process used depends primarily on two factors: firstly on the material used and its specific properties (e.g. material hardness and density) and secondly the desired complexity and the required precision of the part being manufactured.

Other factors that SCHLÖSSER, as a professional manufacturer of technical parts, takes into account when selecting the manufacturing process and material: The desired quantity, the possibility of making changes to the layout or part geometry (e.g. at the development stage) as well as the delivery form, which significantly determines the handling of the components in the customer’s assembly operation.

SCHLÖSSER is active in the punching sector as a manufacturer of short, medium and long production runs. Please note that a specific punching tool is required in each case. For efficiency reasons, this production process therefore delivers particular benefits in medium and long production runs. For this, we have a set of standard tools in stock. Also, with our in-house tool-making shop, we are also able to develop entirely bespoke shapes.

Laser cutting and waterjet cutting are different: Since no tools are required for these production processes, preliminary samples, short production runs as well as high-volume runs of millions of parts can be produced quickly and cost-effectively. Waterjet cutting and laser cutting are also suitable for the manufacture of parts with filigree or elaborate contours. Here, geometry modifications can be implemented economically and quickly, for example during the development phase. Through precise control of the laser beam, it is possible to use laser cutting to simulate multi-layer delivery forms for a subsequent production run.

The applicable production process determines which machines and systems are used to manufacture seals and Technical Parts.

For punching operations, SCHLÖSSER has an exceptionally high-performance range of machines and a team of skilled professionals who can operate them to perfection. That range of machines includes:

At SCHLÖSSER, these machines are divided into highly capable punching departments – by types, sizes and degrees of automation. This enables us economically and efficiently to manufacture seals, punched parts and Technical Parts in short, medium and long production runs.

With waterjet cutting, SCHLÖSSER can also offer a broad range of services:

With laser cutting, SCHLÖSSER also has a name for great manufacturing solutions for seals and Technical Parts:

-> Which materials does Schlösser offer in its portfolio?

In the manufacture of its products, SCHLÖSSER focuses primarily on the following materials (for a more detailed illustration, see XXX/materials):

Please contact us about any particular material-based wishes or requirements you may have. Our experienced team of technical application specialists and service advisers will be pleased to assist you. Here is how we here at SCHLÖSSER precisely adapt the seals and Technical Parts we make to suit your specific fields of application.

The employees at SCHLÖSSER work on a daily basis to achieve the highest possible level of precision and quality for the parts we manufacture. The guideline followed by the entire company is the Zero Defect target. There are also various other standards that identify the technological, qualitative or operational suitability of a manufacturer of seals for defined sectors. Accordingly, SCHLÖSSER is certified with its quality management system in accordance with IATF 16949, ISO 9001 and with the environmental management system defined in ISO 14001.

The focus of our efforts is on:

You can view our certificates as pdf files or, if you need to, you can also download them from our website.

IATF 16949 Plant I certificate (pdf)

ISO 9001 Plant I certificate (pdf)

ISO 9001 Plant II certificate (pdf)

ISO 14001 certificate (pdf)

We continue to produce samples in accordance with the latest VDA guidelines and/or in accordance with the PPAP standard. We are also pleased to use customer-specific plant standards when producing sample parts. Our quality technology department is able to satisfy and document all desired metrological tasks.

In addition, we offer compliance with technical cleanliness requirements for our manufacturing process, all tailored to meet your specific requirements. With various premises from clean areas to cleanrooms, as well as expertise relating to the many different parameters and monitoring options, we are ideally equipped to tackle technically demanding applications in high-end sectors such as electrical engineering, the automotive industry or medical technology.

At SCHLÖSSER, we stand for the high-quality production of a wide variety of technical parts. Individuality and flexibility are among our particular strengths, also in relation to prototyping.

To this end, we develop precisely fitting solutions for the production of seals and Technical Parts based upon customer drawings or samples. We are able to process your requests or to manufacture pre-production parts very rapidly indeed if you provide us with component drawings in digital form, ideally in one of these formats:

As an experienced manufacturer of industrial seals, SCHLÖSSER delivers advantages on several levels: With regard to the specific seal (the punched part or Technical Part), the company can draw on a wide range of materials – enabling it to cater for a very wide range of applications. Due to its high storage capacities, reliable delivery capability can be assured.

SCHLÖSSER also has its own tool shop as well as a capable team of design engineers. This gives SCHLÖSSER very credible credentials as a manufacturer of bespoke seals.

Its high-performance range of machines coupled with its greatest strength, a great team of specialists, combine to ensure that SCHLÖSSER, as a manufacturer of Technical Parts made of plastic, has a long and successful track record with its customers for optimum flexibility and a huge range of applications.

Please note that the boxes marked with an asterisk (*) must be filled in to enable us to process your input properly.

Schlösser GmbH & Co. KG

Wilhelmstraße 8

88512 Mengen/Germany

Schlösser GmbH & Co. KG

Wilhelmstraße 8

88512 Mengen/Germany

Unser jährlicher Outdoor-Tag ist eines der Highlights während der Ausbildung. Es erwarten dich darüber hinaus noch vielfältige Aktivitäten, wie z. B. ein Fahrsicherheitstraining, Betriebssport, gemeinsame Grillfeste und Essen, etc.

Unsere Bezahlung während der Ausbildungs- und Studienzeit kann sich sehen lassen. Neben einer monatlichen Vergütung erhältst du Urlaubs- und Weihnachtsgeld sowie weitere attraktive Sonderzahlungen und Prämien. Auch besondere Leistungen werden von uns belohnt – neben einer jährlichen Sonderzahlung für gute Noten erhalten Kammersieger und Jahrgangsbeste einen Sonderurlaubstag sowie Eintrittskarten für den Europapark in Rust.

Bei uns wird FAMILIE großgeschrieben. Wir leben einen kollegialen und freundschaftlichen Umgang, gegenseitigen Respekt und Wertschätzung sowie Hilfsbereitschaft – unabhängig jeglicher Hierarchieebenen. Bei uns gehörst du von Anfang an dazu.

Während deiner Ausbildung- und Studienzeit geben wir dir die Chance, dich zielgerichtet zu entwickeln – für Positionen die deinen Stärken am besten entsprechen. Nach Beendigung deiner Ausbildung bzw. deines Studiums ist dein Weg bei uns noch lange nicht zu Ende. Schließt du deine Ausbildung bzw. dein duales Studium erfolgreich ab und zeigst auch in den Fachabteilungen gute Leistungen, möchten wir dich im Anschluss in einer Fach- oder Führungsfunktion übernehmen.

Belegte Brötchen, Müsli, Wurstsalate, frische Salate und warme Speisen – die Auswahl in unserer Betriebskantine ist nahezu unbegrenzt. Mit einem großzügigen Arbeitgeberzuschuss sind die Preise besonders attraktiv.

Du wirst in den einzelnen Fachabteilungen von kompetenten Mitarbeitenden betreut, die täglich ihr Bestes geben, um unsere Auszubildenden und Studierenden zu qualifizieren. Deine individuelle Betreuung wird ergänzt durch einen persönlichen Paten und deine Ausbilder.