Mechanical engineering is one of the leading industrial sectors, one where further development never ceases. Technology, expertise, the art of engineering – mechanical engineering is known for all of those. This is a sector spanning a vast and diverse range of applications, from drive technology to workpiece machining, production and quality control, from metal to wood or plastic.

Seals and technical parts play an important role in mechanical engineering from specific machinery and plant to their upstream and downstream peripherals. The name SCHLÖSSER is a guarantor of quality and versatility. Our technical parts also embody total quality, they are Made in Germany and they are often the outcome of high-end engineering processes.

Quite simply, technical parts made by SCHLÖSSER can be used in very many mechanical engineering contexts. We field a wide range of standard products, and our team of technical experts can also tackle specialised requirements flexibly and rapidly. This is what makes us a top manufacturer and supplier on the mechanical engineering sector.

TECHNICAL PARTS made by SCHLÖSSER are used in:

The custom seal solutions we offer enable us to keep pace with the extremely demanding requirements in electrical drivelines. Our high-quality products ensure that we can assure extended service lives and greater machine reliability coupled with lower friction losses and performance impairment.

Seal integrity, reliability and efficiency are crucial factors in the drive technology sector.

In addition to assembly errors, corrosion and progressive leakage constitute potential hazards here, especially with gearbox motors that are often in operation over extended periods of time. Technical parts made by Schlösser are therefore, quite simply, indispensable.

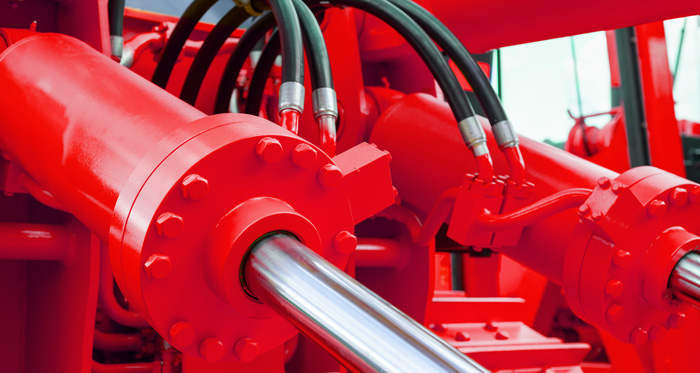

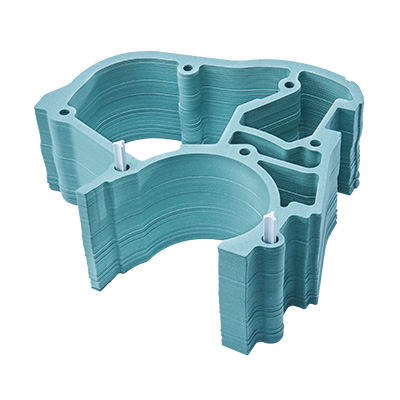

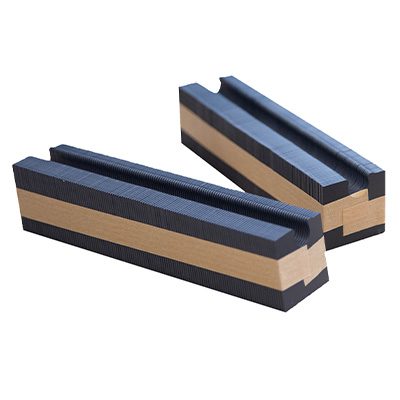

The choice of precisely the right seal to achieve optimum functionality for your hydraulic or pneumatic cylinders depends on three things. You need to have a comprehensive overview of operating conditions, movement sequences and the interaction of all components involved. As well as the primary seal function, the correct choice of material, physical performance in relation to operating temperature and operating pressure and an understanding of the properties required all combine to assure low friction losses and good resistance to abrasive wear. We are able to provide you with an optimum solution in terms of quality and cost-effectiveness because we can access a comprehensive material portfolio sourced from renowned suppliers, we have a range of high-performance machines and we employ a very capable team of highly skilled experts and specialists. The name SCHLÖSSER is a byword for the very finest quality of technical parts made from plastic – today and into the future.

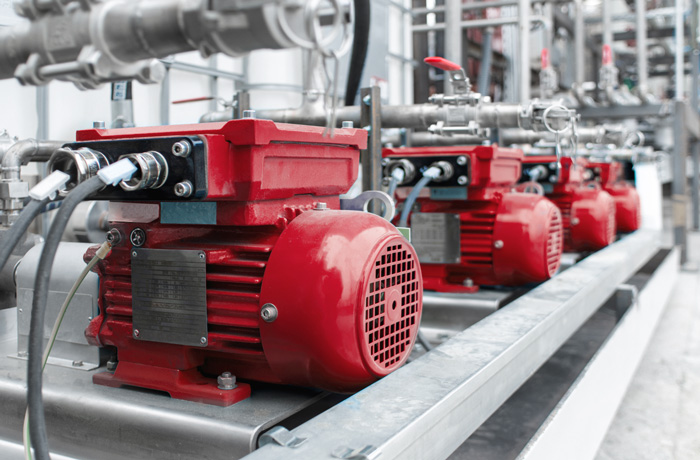

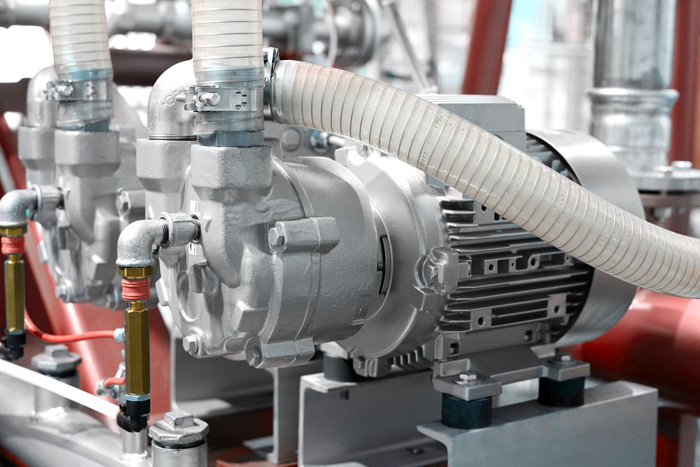

Reliability is the key to achieving cost-effectiveness with any process technology system. Seals have an important role to play in reducing plant downtime and the associated loss of production. For example, they can ensure that liquids remain sealed in a container where shafts rotate in stationary housings, or occasionally where housings rotate around a stationary shaft.

Proper sealing also delivers significant benefits in terms of operational safety and the service life of a pump.

In vacuum technology, seals are used to prevent the ingress of ambient air into the vacuum. Depending on application and pressure range, various designs of seals are available.

The performance capability in the robotics sector is increasing progressively and new fields of application are getting added all the time. As a component in automated and digitally networked production and logistics systems, reliable functional integrity is an essential requirement. Thanks to the specific choice of material and component designs that are perfectly matched to each application, ultimate standards of functionality can be achieved consistently. Our sealing solutions can withstand big fluctuations in temperature and high speeds. This enables them to improve cost-effectiveness by a substantial amount. Added to this, our seals can prevent leakage and resultant malfunctions. This in turn eliminates downtime and its associated costs.

Movement and continuous operation cause wear and tear on many components associated with industrial lift truck technology.

Pallet trucks and forklifts are good examples, engaged in constant movement at high pressure which, as time goes by, leads to problems with the raising and lowering of forklift tines or with oil loss. Which in turn entails the need for regular maintenance.

Although for the most part invisible, but no less essential for that, our solutions contribute in many ways towards satisfying the quality demands of intralogistics while at the same time minimising or even preventing extended periods of equipment downtime.

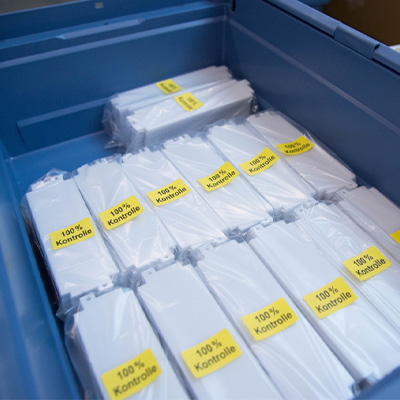

For the most part, companies that operate on the mechanical engineering sector move within the boundaries of high-end delivery chains: These are defined not only by ultimate standards of quality but also by absolute deadline compliance. Here, SCHLÖSSER constitute the ideal components. Firstly, we provide high-quality products and secondly, our delivery performance is exemplary thanks to our high inventory capacities. Our experienced team is also delighted to assist with one-off production runs and the development of prototypes. With our clean room production facilities, we can also manufacture products for particularly sensitive sectors.

SCHLÖSSER seals and Technical Parts for mechanical engineering sector:

Are you interested in our seals and technical parts? Or do you need a solution from SCHLÖSSER for a specific requirement? If so, please just get in touch with us: we are here to assist you.

Tel. +49 7572 606-0 Mon.-Thu. 8:00 a.m. – 4:30 p.m. Fri. 8:00 a.m. – 4:00 p.m. info@schloess.deThere are virtually no limits on the fields of application for SCHLÖSSER seals, technical parts and our other products. In many sectors, our products are an indispensable part of a great many applications and functions, e.g. in the automotive, electrical and sanitation sectors – and the list goes on. We are also pleased to assist you with highly specific individual customer solutions with our experienced team of advisers who have decades of experience, with a wide range of materials and production processes. Here at SCHLÖSSER we make your requirement our business.

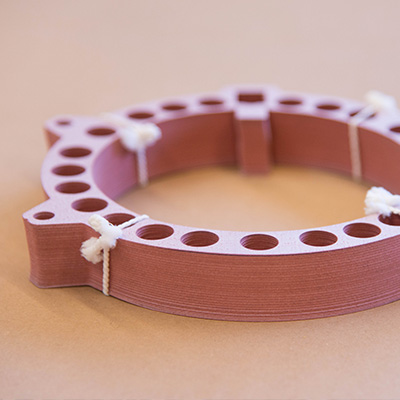

The world of seals and technical plastic components is a multi-faceted one. Also true of our production processes. Depending on the material or the desired quantity and form of delivery, SCHLÖSSER can provide you with the optimum production process for manufacturing the parts you need efficiently and to a high standard of quality.

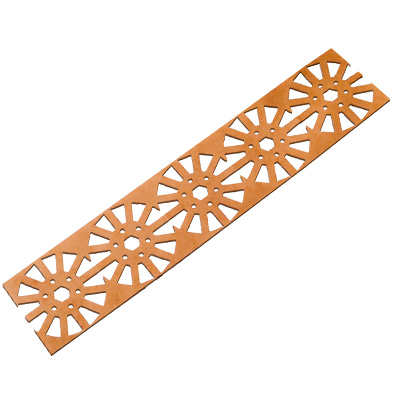

Ideal for producing small quantities or prototypes rapidly and cost-effectively. This broad range of options underscores the high level of flexibility that laser cutting is able to offer.

Efficient processes – the stroke and rotary method of blade cutting as well as shear cutting method – at various levels of automation: quick, precise and cost-effective for short, medium and long production runs.

As with laser cutting, no dedicated tool is required. Geometric modifications can be implemented quickly and cost-effectively, ideal for the manufacture of short production runs (e.g. samples, mini-series).

With over 1,500 different materials from renowned manufacturers, the name SCHLÖSSER stands for an almost infinite range of product solutions extending from the manufacture of seals and technical parts made of plastic. SCHLÖSSER has the solution, from seals or damping in displays to heat management or venting in batteries to insulation or EMC shielding in a wide variety of electronic components and much more.

Please note that the boxes marked with an asterisk (*) must be filled in to enable us to process your input properly.

We supply what you need: exactly as you would like it. The same applies to the form of delivery as to our products and solutions: individuality is our trump card. Depending on material and quantity, we offer these choices:

Schlösser GmbH & Co. KG

Wilhelmstraße 8

88512 Mengen/Germany

Schlösser GmbH & Co. KG

Wilhelmstraße 8

88512 Mengen/Germany

Unser jährlicher Outdoor-Tag ist eines der Highlights während der Ausbildung. Es erwarten dich darüber hinaus noch vielfältige Aktivitäten, wie z. B. ein Fahrsicherheitstraining, Betriebssport, gemeinsame Grillfeste und Essen, etc.

Unsere Bezahlung während der Ausbildungs- und Studienzeit kann sich sehen lassen. Neben einer monatlichen Vergütung erhältst du Urlaubs- und Weihnachtsgeld sowie weitere attraktive Sonderzahlungen und Prämien. Auch besondere Leistungen werden von uns belohnt – neben einer jährlichen Sonderzahlung für gute Noten erhalten Kammersieger und Jahrgangsbeste einen Sonderurlaubstag sowie Eintrittskarten für den Europapark in Rust.

Bei uns wird FAMILIE großgeschrieben. Wir leben einen kollegialen und freundschaftlichen Umgang, gegenseitigen Respekt und Wertschätzung sowie Hilfsbereitschaft – unabhängig jeglicher Hierarchieebenen. Bei uns gehörst du von Anfang an dazu.

Während deiner Ausbildung- und Studienzeit geben wir dir die Chance, dich zielgerichtet zu entwickeln – für Positionen die deinen Stärken am besten entsprechen. Nach Beendigung deiner Ausbildung bzw. deines Studiums ist dein Weg bei uns noch lange nicht zu Ende. Schließt du deine Ausbildung bzw. dein duales Studium erfolgreich ab und zeigst auch in den Fachabteilungen gute Leistungen, möchten wir dich im Anschluss in einer Fach- oder Führungsfunktion übernehmen.

Belegte Brötchen, Müsli, Wurstsalate, frische Salate und warme Speisen – die Auswahl in unserer Betriebskantine ist nahezu unbegrenzt. Mit einem großzügigen Arbeitgeberzuschuss sind die Preise besonders attraktiv.

Du wirst in den einzelnen Fachabteilungen von kompetenten Mitarbeitenden betreut, die täglich ihr Bestes geben, um unsere Auszubildenden und Studierenden zu qualifizieren. Deine individuelle Betreuung wird ergänzt durch einen persönlichen Paten und deine Ausbilder.