Home » Applications » Medical diagnostics

Whether for diagnostics, therapeutics or acoustics – medical applications need the tiniest of components for sealing and damping that also need to be robust, hygienic and safe.

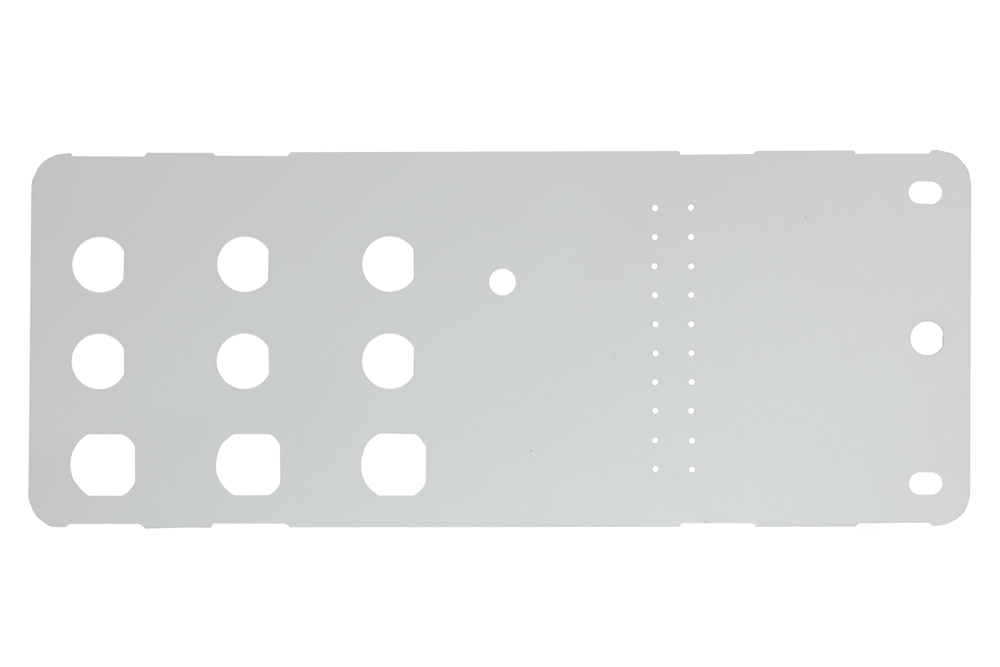

Lab-on-a-chip designates a microfluid system that integrates on a single chip one or more analyses that are normally performed in a laboratory. With this technology, even minute quantities of liquid can be analysed completely and automatically on a chip. With the help of our part, safe sealing of the housing can be guaranteed.

The special feature here is that the product is manufactured under cleanroom conditions, preventing contamination that could possibly affect the result.

These seals, using in micropumps, seal the channels inside a valve, preventing medium from escaping while the valve is closed. The uses of these seals include liquid pumps, gas pumps for food and in the laboratory.

These seals, using in micropumps, seal the channels inside a valve, preventing medium from escaping while the valve is closed. The uses of these seals include liquid pumps, gas pumps for food and in the laboratory.

High-quality solutions are essential for diagnostic applications in medical technology that are required to deliver reliable and precise evaluation results for patients, the key to providing successful treatment.

SCHLÖSSER now assures compliance with requirements on technical cleanliness, up to the prevention of RNA and DNA on supplied products, using individually planned systems coupled with dependable analysis results.

We do more than just manufacture your Technical Parts to the highest standards of quality. We also assemble, inspect and clean them reliably – for example in our ISO Class 8 cleanrooms.

Naturally, our procedural operations extend right across the supply chain: We do not just apply high standards to production and processing but also to the corresponding sequence of processes and logistics extending from the properties of unprocessed materials all the way through to delivery and assembly in our production facility.

You absolutely can place your full confidence in us as a highly capable partner for projects involving enhanced levels of technical cleanliness. Under cleanroom conditions, we can provide you with a wide range of services for your products.

SCHLÖSSER can supply a diverse range of materials from its own portfolio but it can also procure anything else that customers might wish to use. When doing so, we ensure that we use materials with an established track record for a given application, ones that meet quality and availability criteria. We are well positioned to do this through our capable network of partners.

The world of seals and technical plastic components is a multi-faceted one. Also true of our production processes. Depending on the material or the desired quantity and form of delivery, SCHLÖSSER can provide you with the optimum production process for manufacturing the parts you need efficiently and to a high standard of quality.

Ideal for producing small quantities or prototypes rapidly and cost-effectively. This broad range of options underscores the high level of flexibility that laser cutting is able to offer.

Efficient processes – the stroke and rotary method of blade cutting as well as shear cutting method – at various levels of automation: quick, precise and cost-effective for short, medium and long production runs.

As with laser cutting, no dedicated tool is required. Geometric modifications can be implemented quickly and cost-effectively, ideal for the manufacture of short production runs (e.g. samples, mini-series).

Which other applications and function are of interest for sensors and actuators? Take a look around!

Please note that the boxes marked with an asterisk (*) must be filled in to enable us to process your input properly.

Schlösser GmbH & Co. KG

Wilhelmstraße 8

88512 Mengen/Germany

Schlösser GmbH & Co. KG

Wilhelmstraße 8

88512 Mengen/Germany

Unser jährlicher Outdoor-Tag ist eines der Highlights während der Ausbildung. Es erwarten dich darüber hinaus noch vielfältige Aktivitäten, wie z. B. ein Fahrsicherheitstraining, Betriebssport, gemeinsame Grillfeste und Essen, etc.

Unsere Bezahlung während der Ausbildungs- und Studienzeit kann sich sehen lassen. Neben einer monatlichen Vergütung erhältst du Urlaubs- und Weihnachtsgeld sowie weitere attraktive Sonderzahlungen und Prämien. Auch besondere Leistungen werden von uns belohnt – neben einer jährlichen Sonderzahlung für gute Noten erhalten Kammersieger und Jahrgangsbeste einen Sonderurlaubstag sowie Eintrittskarten für den Europapark in Rust.

Bei uns wird FAMILIE großgeschrieben. Wir leben einen kollegialen und freundschaftlichen Umgang, gegenseitigen Respekt und Wertschätzung sowie Hilfsbereitschaft – unabhängig jeglicher Hierarchieebenen. Bei uns gehörst du von Anfang an dazu.

Während deiner Ausbildung- und Studienzeit geben wir dir die Chance, dich zielgerichtet zu entwickeln – für Positionen die deinen Stärken am besten entsprechen. Nach Beendigung deiner Ausbildung bzw. deines Studiums ist dein Weg bei uns noch lange nicht zu Ende. Schließt du deine Ausbildung bzw. dein duales Studium erfolgreich ab und zeigst auch in den Fachabteilungen gute Leistungen, möchten wir dich im Anschluss in einer Fach- oder Führungsfunktion übernehmen.

Belegte Brötchen, Müsli, Wurstsalate, frische Salate und warme Speisen – die Auswahl in unserer Betriebskantine ist nahezu unbegrenzt. Mit einem großzügigen Arbeitgeberzuschuss sind die Preise besonders attraktiv.

Du wirst in den einzelnen Fachabteilungen von kompetenten Mitarbeitenden betreut, die täglich ihr Bestes geben, um unsere Auszubildenden und Studierenden zu qualifizieren. Deine individuelle Betreuung wird ergänzt durch einen persönlichen Paten und deine Ausbilder.